Injection molding and machining are two of the most common manufacturing processes used today. Both have their advantages and limitations when it comes to factors like cost, production time, design flexibility, part complexity, precision, and more.

Is injection molding cheaper than machining? The short answer is – it depends. In general, injection molding has a higher startup cost but lower per-unit cost at production volumes above 1,000-10,000 parts. Machining is more affordable for prototyping and short production runs under 1,000 parts.

However, accurately determining which process is cheaper requires a detailed analysis of all cost factors over the entire product lifecycle. In this guide, as a professional plastic injection molding service provider, we’ll dive into everything you need to consider when deciding between injection molding vs machining based on cost and other critical factors.

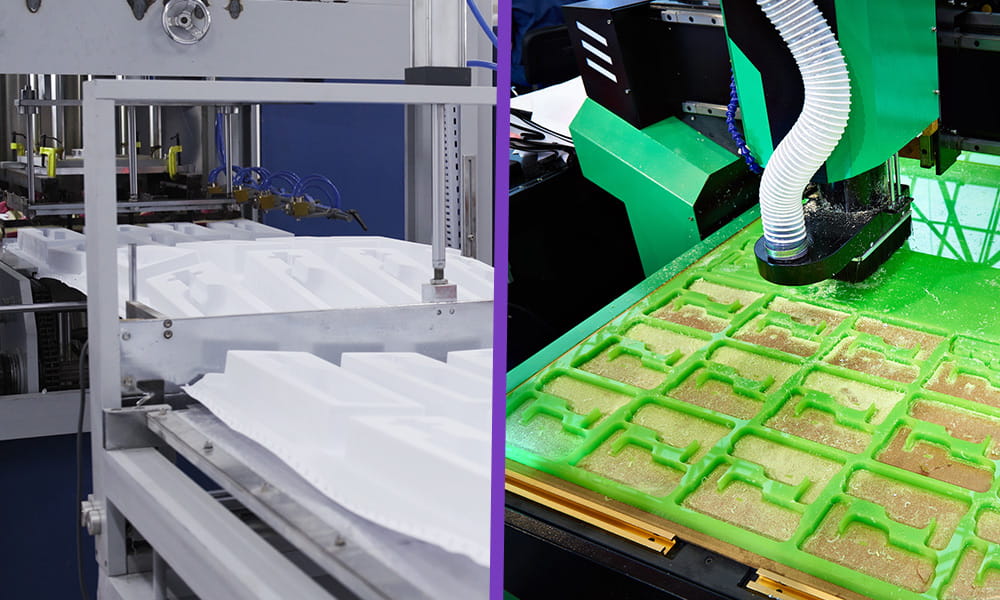

How Injection Molding and Machining Work

Before comparing costs, let’s quickly summarize how each process works:

Injection Molding Overview

Injection molding produces plastic parts by injecting molten plastic material at high pressure into a mold cavity. The plastic solidifies into the shape of the mold as it cools. Parts can have complex geometries and require minimal labor for post-processing.

The main components of injection molding are:

- Mold – Custom machined cavity that shapes the molten plastic into parts

- Injection unit – Heats, melts, and injects plastic into the mold

- Clamping unit – Opens, closes, and clamps mold during injection

Machining Overview

Machining is a subtractive process where rotary cutters remove material from a solid block to achieve a desired part shape. Common machine tools used include mills, lathes, drills etc. Machining produces durable and high precision metal or plastic parts.

The key components of machining processes like CNC milling are:

- CNC machine – Computer controlled system directing tool movement

- Cutting tools – End mills, drills etc. that cut away material

- Raw material – Metal or plastic block subtracted to make parts

Now that we’ve looked at both processes at a high-level, let’s analyze the cost considerations in detail.

Injection Molding vs Machining: Cost Comparison

Several factors contribute to determining if injection molding or machining offers the most cost-effective route for production. These include:

1. Upfront Tooling Cost

- Injection molding – Designing and fabricating an injection mold is expensive, ranging from $1,000 for simple single-cavity molds that produce one part per cycle to $100,000+ for complex multi-cavity molds.

- Machining – Minimal tooling costs beyond fixturing and workholding devices to secure raw material blocks. Significantly lower investment than injection molds.

- Verdict – Machining wins for lower startup costs.

2. Cost Per Unit

- Injection molding – Cost per part drops exponentially with volume as expensive mold cost is amortized. For example, cost per part for volumes ~10,000+ can be as low as $0.50-1.

- Machining – Each part requires dedicated machine time for shaping so cost per unit stays relatively fixed regardless of volume. Average range is $10-$100 per piece depending on complexity.

- Verdict – Injection molding substantially lower cost per unit at mid-to-high volumes.

3. Secondary Processing

- Injection molding – Molded parts ejected from sophisticated molds often require no additional work before shipment. Reduces labor costs.

- Machining – Additional bench work like debarring, tapping holes, finishing, etc. frequently required as parts removed manually. Increases costs.

- Verdict – Injection molding faster and cheaper.

4. Economies of Scale

- Injection molding – Multi-cavity molds increase production per cycle. Larger machines mold higher volumes per hour. This scales efficiently.

- Machining – Limited flexibility to scale production as parts made individually. Output reliant on available machine capacity.

- Verdict – Injection molding easily ramps output, machining less scalable.

5. Design Changes

- Injection molding – Expensive and time consuming to modify steel molds. Alterations can cost thousands and take weeks.

- Machining – Easy to update CNC programs and re-machine parts. Provides greater flexibility.

- Verdict – Machining accommodates changes with significantly lower costs.

6. Material Wastage

- Injection molding – Recycles sprues, runners and unused material. Very little wastage relative to other processes.

- Machining – Raw material blocks reduced to chips and swarf. Comparatively higher material wastage.

- Verdict – Injection molding edges out machining.

Considering these key cost factors, machining typically makes financial sense for annual part quantities up to 1,000 pieces whereas injection molding is cheaper at mid-to-high volumes of 10,000+ units. The break-even point depends greatly on part size, complexity, order variability etc.

Let’s recap when each process offers greater value:

Injection molding more affordable for:

- Mid-to-high production volumes (~1,000+ units)

- High labor costs (reduced manual effort)

- Large or bulky parts (higher material savings)

- Established designs (no iteration required)

Machining more affordable for:

- Low annual part quantities (<1,000 units)

- Simple small-to-medium sized parts

- Frequent design changes

- Early product development

With the costs contrasted, let’s compare some of the other differentiating factors between these manufacturing methods.

Other Comparison Metrics Between Injection Molding and Machining

Beyond cost models, several technical and operational factors require consideration when deciding between injection molding vs machining:

1. Production Timelines

- Injection molding – Slower initial timeline for mold design/build. Subsequent cycles rapidly produce parts.

- Machining – Immediate production start as no tooling required. But slower per-part rate.

- Verdict – Injection molding higher long term throughput.

2. Part Complexity

- Injection molding – Can produce complex geometries by shaping bends, holes etc into mold.

- Machining – Limited in creating complex internal cavities due to tool accessibility constraints.

- Verdict – Injection molding can handle greater complexity.

3. Dimensional Tolerances

- Injection molding – Typical tolerance ±0.005 inches. Suitable for many commercial applications.

- Machining – Exceptional precision of ±0.001 inches or finer easily achievable.

- Verdict – Machining superior for ultra-high precision parts.

4. Material Range

- Injection molding – Greatest diversity among all plastic molding processes. But limited to polymers.

- Machining – Vast range of machinable metals, plastics, composites etc.

- Verdict – Machining supports vastly wider material selection.

When deciding between these two manufacturing routes, consider the impact these technical factors will have on your application.

Best Applications for Each Process

The most suitable process depends significantly on your specific product requirements and operating context. However, some common best-fit applications include:

Injection molding ideal for:

- Cost-sensitive high volume plastic parts like containers, enclosures etc.

- Tight-tolerance consumer products – electronics, automotive, appliances

- Medical disposables, precision plastic instrumentation

Machining well-suited for:

- Low/mid-volume precision metal components – aerospace, defense

- Short-run plastic parts with surface finish importance – orthodontics

- Frequent design iterations during product development

- Small batches needed urgently – machine tooling, robotics

The choice between injection molding vs machining for production should factor in all cost, capability and business considerations that apply. With this guide examining all comparison points in-depth, you hopefully feel better positioned to make the right strategic decision by your manufacturing needs.

Consulting an expert can also help assess your specific scenario, production volumes, quality needs etc. to provide data-backed guidance on selecting the ideal process. Making informed, insight-led choices between injection molding and machining ensures achieving operational efficiency and cost objectives.

Now over to you – what other factors would you consider in your decision process when weighing up these critical manufacturing alternatives? Share your thoughts and questions in the comments section below!