One-stop Solution for Medical Silicone Molding and Medical Silicone Parts Manufacturing

We are a professional medical silicone molding manufacturer and have clean rooms for your medical silicone products project.

Full Manufacturing Plants For Medical Silicone Molding

Medical Silicone Molding Parts

LSR injection molding parts made by medical-grade silicone gel

Silicone Pacifier Made Medical Silicone Molding

LSR injection medical molding can make high-quality baby silicone pacifier

Medical Silicone Molding for Medical Silicone Valve

LSR molding can make high precision medical silicone valve.

Medical Pressure Ball made by Medical Silicone Molding

Liquid silicone molding can produce high standard medical pressure ball

Medical Silicone Molding Baby Silicone Toothbrush

Baby silicone toothbrush made by liquid silicone molding with medical-grade silicone gel

Medical Oxygen Mask made by Medical Silicone Molding

Liquid silicone rubber injection molding can make high-quality medical breathing mask

Baiwe:Your Reliable Medical Silicone Molding Provider and Medical Silicone Parts Manufacturer

As one of the best medical silicone molding companies in China, we passed full certifications, like BSCI and our products are approved by FDA and SGS. Your medical silicone molding project will be guaranteed in all ways.

The silicone raw material is very important to medical silicone molding, we select the top quality of liquid silicone material which is approved by the FDA. We have a different hardness of silicone raw material for your options, it will depend on which silicone molding method you chose and your application for medical silicone molding.

If you are strictly on silicone flashes and parting line for medical silicone parts, we will be your best choice, we have been committed to improving high precision silicone molding, the molded sizes tolerance can be up to ±0.01mm, our liquid injection medical silicone molding can achieve the smallest silicone burrs and parting line.

Pls kindly send us your 2D/3D designs right now, we will offer you the most professional solutions!

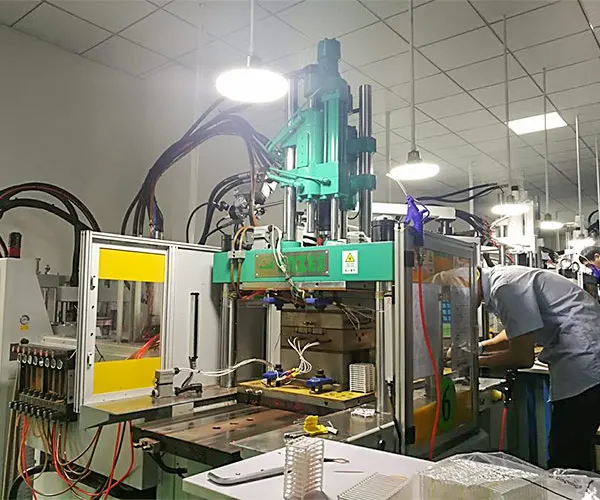

Liquid Silicone Rubber Injection Molding Machine

Liquid Silicone Rubber Injection Molding Machine

Die Cutting Machine

Liquid Silicone Rubber Injection Molding Machine Side

Printing Workshop

Mold Making Machine

Die Cutting Machine

Die Cut Silicone Products Tester

Silicone Keypad Lifetime Tester

Tensile Tester

CCD Tester

Insulation Resistance Tester

Related Products

Medical Silicone Molding-Baby Toothbrush

Medical Silicone Molding-Baby Mild Bottle

Medical Silicone Molding Baby Spoon

Benefits of Medical Silicone Molding for Consumer Products

Baiwe also can offer medical silicone molding services for consumer products, like silicone baby pacifier, kids toothbrush, and other silicone rubber products.

There are a lot of benefits of medical silicone molding to make consumer products, it’s much more softer and comfortable to touch. The medical-grade silicone material is more safer and efficient to manufacture in a short time. These benefits can bring you a bigger market share.

Get us our best solution for your silicone molded parts project right now.

We Can Offer Many Kinds of Silicone Molding For Your Projects

Besides medical silicone molding, we also can offer you other silicone molding services and production as per your demand. Like silicone overmolding, silicone transfer molding, plastic injection molding.

Send us your requirement right now!

Medical Silicone Molding-The Ultimate FAQs Guide

The healthcare industry has seen an increase in the usage of silicone. It is bio-compatible and patient-friendly. Below are some questions you may have about medical silicone molding:

- What Is Medical Grade Silicone?

- What Are The Types Of Medical Silicones?

- Why Is Silicone The Preferred Material For The Medical Industry?

- What Are The Speciality Applications Of Medical Grade Silicone?

- What Is The Production And Molding Method Of Medical Silicone?

- How Long Does Injection Molding Last?

- Liquid Silicone Rubber vs High Consistency Rubber

- Does Consistency Matter In Medical Silicone Injection Molding?

- Can You Use Medical Grade Silicone To Make Prosthetics?

- Is Medical Grade Silicone More Expensive Than Thermoplastic Elastomers?

- What Questions Should You Ask When Considering A Supplier For Medical Silicone Molding?

What Is Medical Grade Silicone?

The silicone that is capable of or has passed a set of standardized biocompatible tests can be called medical grade silicone. Many companies using this term means these two things:

- Medical-long Term Implantable Material: This term is used for a material that stays in the body as a part of an implantable device. Since it’s very pure, it’s extremely expensive for usage in food-grade.

- Medical Grade: It is more technically called medical healthcare grade, class VI silicone, this silicone can be used to manufacture a number of products such as scuba mouthpieces, water pipes, and skin contact products.

What Are The Types Of Medical Silicones?

Below are the three types of medical silicones:

- Liquid Silicone Rubber: It is the main silicone used. It is also known as Liquid Injection Molding. LSR works well with injection molding but we can also mold parts in compression molding or transfer molding. LSR has a consistency that is between warm syrup and cold molasses. It’s properties are broad because of the high number of materials. They range from 10 to 80 Shore A hardness.

- High Consistency Rubber: Also called high silicone rubber, is a material with a high viscosity. Its consistency is a lot like formable clay. These materials have a high durometer that starts from 30 shore A or goes higher. This material is suitable for transfer or compression molding parts for prototyping and production. However, it needs more handling when it comes to mixing and molding materials. HCR is not suitable for injection molding.

- Room Temperature Vulcanizing: RTV has a low viscosity which has a consistency of warm maple syrup in some instances. As the name implies, it can be cured at room temperature. The process can also be sped up through process heat. RTV usually has a lower durometer and is typically used for encasing electronics that are temperature sensitive or in rapid prototyping. Because of the low viscosity, high curing rate, the suitable method for them is compression molding and casting.

Why Is Silicone The Preferred Material For The Medical Industry?

Silicone is the material of choice for the medical industry when it comes to medical devices and medical device parts because it is very durable and easy to mold through various methods. It has a wide temperature range, chemical resistance, tear resistance, varying degrees of durometer, and a low toxic level.

Moreover, silicone works well with the human body, is suited to the tissues with a low response when implanted, doesn’t give way to bacteria growth, and adjusts to bodily fluids. Liquid Silicone Rubber is also perfect for long-term and short-term usage. You can use silicone in a wide range of products.

What Are The Speciality Applications Of Medical Grade Silicone?

Medical grade silicone is perfect for applications that are flexible, soft to the touch, biocompatible, have a high cycle life with a stable behavior throughout varying temperatures. These could be:

- Seals and gaskets

- Valves / Septum

- Tubing

- Encapsulation of electronics

- Catheters

- Implant components

- Syringe pistons

- Menstrual cups

- Respiratory masks

What Is The Production And Molding Method Of Medical Silicone?

When it comes to molding medical liquid silicone, additional equipment is required other than the standard injection presses in which you mix the 2 basic components. The additional equipment is a crosslinking agent and a catalyst that is observed through an electronic unit that controls the combining and temperature parameters.

Medical silicone is suitable for usage after it has undergone various high temperature post-curing treatments that remove any charged substances found while also improving the mechanical characteristics of the product.

How Long Does the Medical Grade LSR Last?

Medical grade LSR has three types:

- Limited Exposure: This type is reserved for devices that will touch the skin, mucosal membrane, or breached surfaces. It has a short service life, ranging from 24 hours or less.

- Prolonged Exposure: This material is also called “healthcare grade”. It undergoes tests like haemolysis, genotoxicity, toxicity, and intramuscular implantation with histopathology. It has a longer life compared to the above type, ranging from 24 hours to 30 days.

- Permanent Contact: It is also called “long-term implantable”. This type has to undergo physicochemical and biological tests. It goes through more tests compared to prolonged exposure and even has tests for carcinogenicity, chronic toxicity, and developmental toxicity.

Liquid Silicone Rubber vs High Consistency Rubber

Viscosity is the main thing that differentiates between liquid silicone rubber (LSR) and high consistency rubber (HCR). It has a huge outcome on the equipment and processes required to manufacture both of these elastomers.

Since LSR has a lower viscosity compared to HCR, injection molding is the suitable method for it. Its favorable handling properties and low shrinking rates make it perfect for making incredibly complicated geometrics and intricate products.

LSR’s low viscosity rate makes it suitable to add additives into it. Additives that you can easily add into LSR include colorants, desiccants, barium, and pharmaceuticals such as hormones or steroids. This makes LSR the perfect choice for medical devices globally.

Because LSR has a low manufacturing cost compared to HCR and is compatible with formulas, it is many medical companies’ preferred choice. However, using either liquid silicone rubber or high consistency rubber is a case by case scenario.

Does Consistency Matter In Medical Silicone Injection Molding?

Yes, it does. You cannot compromise when it comes to consistency and quality because these products are crucial to the health of many people using them. Choosing a manufacturer of low quality and less experience will result in jeopardizing a person’s health and may also result in law suits.

The healthcare industry has great requirements for its devices hence tight tolerances and cleanliness have little room for errors. A manufacturer that gives priority to quality and repeatability in its medical devices will deliver products that are consistent with its customers.

Can You Use Medical Grade Silicone To Make Prosthetics?

Prosthetics improve a patient’s mobility in life by allowing them to conduct everyday tasks. Prosthetics, in their nature, are in contact with the patient’s skin for long hours. Hence those areas which are touching the human skin need to be of high biocompatible material.

Similarly, the liner sections of the prosthetic limbs that need to fit against the human limb should be compatible enough to absorb the everyday shock that comes with regular use which may also include running.

Silicone possesses many of the abilities that a prosthetic requires, these range from various durometers, chemical resistance, durability, biocompatibility, and a wide temperature range. Because of all of these abilities, liners for artificial limbs are usually made from silicone.

And, medical grade silicone has the additional ability to be exceptionally pure and clean which is a requirement for safe long term contact with the patient’s body.

Is Medical Grade Silicone More Expensive Than Thermoplastic Elastomers?

Yes. Medical grade silicone is expensive compared to thermoplastic elastomers. However, how long the material will last also has an effect on the cost of the material.

A short term implantable material will cost 5 to 10 times as much as contact grade material while a long term implantable material will cost 10 or more times the price of the short term implantable material. And, if we are talking about drug eluting silicones, the price reaches tens of thousands of dollars.

What Questions Should You Ask When Considering A Supplier For Medical Silicone Molding?

When choosing a manufacturer, you should consider asking yourself the following questions:

- Are there any inspections and standards my products require to meet?

- Does the manufacturer have ISO, FDA, and REACH certificates and compliances?

- Has the manufacturer ever made any products in my industry and how experienced are they?

- Does the manufacturer possess all the latest machinery and quality software?

- Does the manufacturer have a good quality record?

- If there are reword issues, how long does it take for them to fix them?

- What is the manufacturer’s preventative maintenance plan for your injection mold?

Another thing to look for is the material they are using. Whether the material used is of raw quality or not is crucial. Advanced tech and a clean workstation are other things to consider for quality. A clean workstation keeps contamination at bay and controls air quality.

Advance and automatic technology during processing also improve quality. For instance, a computer-controlled program can optimize many operations like measuring, mixing, and sampling to make sure the batch is consistent and is repeated throughout from batch to batch.