We Provide Plastic Injection Molding & Manufacturing Service in China for Customers in Various Industries.

Baiwe is one of the best plastic injection molding manufacturers in China,we can custom made wide range of plastic parts.

Plastic Injection Molding in China

Injection molding products refer to the general term for various products that are formed by heating and plasticizing molten plastic with an injection molding machine, and then injecting it into the mold cavity. After cooling and solidification, the products are demolded. Various products are injection molded by injection molding machines.

After years of development, China’s plastic molding industry has formed a complete industrial system, and its output has continuously ranked first in the world, making it a major producer, consumer and exporter of plastics in the world. After 20 years of development, Baiwe has become one of China’s top injection molding companies.

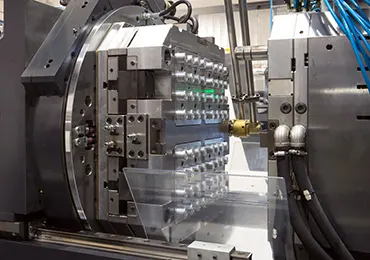

In-house Tooling Workshop

We are fully with mold making equipment,such as CNC,EDM,wire cutting, drilling machines, and tapping machines etc.

Advanced Plastic Injection Molding Machine

We have over 50 plastic injection molding machines in different tons, and capable of making vairous kinds of plastic parts.

Large Part Injection Molding

We have big plastic injection molding machines for making large plastic parts for our clients,the machine is up to 3000 tons,it can make over 35kgs part,the length can be up to 250cm.

China Plastic Pnjection Molding Medical Parts

We have 100k grade clean workshop for manufacturing plastic medical parts.

China ABS Injection Molded Plastic Parts

We have made over 100 plastic materials product for our clients.

China Precision Plastic Injection Molding

Baiwe provide turnkey plastic injection molded product for you.We can do high precision plastic parts,tolerance can be up to ±0.001mm.

Baiwe-The One of the Best Plastic Injecttion Molding Companies in China

Baiwe as a professional plastic mould manufacturer in China, has rich experience in plastic injection OEM and molding and manufacturing. The service that we can offer is as follows,

3D Mold Design: We can offer mold design service if you have physical plastic parts.

Mold DFM Analysis: Baiwe will provide Mold DFM Analysis to evaluate whether a plastic product is suitable for injection molding. DFM analysis is a perfect process to let you know the riskiness of injection molding; knowing the riskiness of injection molding ahead of time will help to reduce waste costs.

Prototype Plastic Injection Molding: We have full equipment, such as 15 sets of CNC machines,10 EDM machines, high precision milling machines, etc, which can make sure your low volume plastic molding project is done well. We also have 3D printers that can make low-volume plastic injection molding.

Plastic Injection Molding: Baiwe has 15 plastic injection machines that can suit big plastic mold and small plastic mold.

Injection molding plastic products manufacturing and assembly: We can make various injection molding plastic parts and assembly services for your project.

What We can Make

Custom Plastic Molded Fliter

Black Plastic Molded Parts

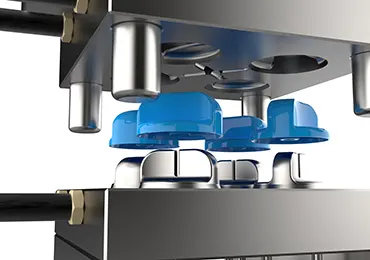

Plastic Injection Molding Lids

The Plastic Injection Molding Process

There is mainly 5 process of plastic injection molding.

Step 1- clamping process

the pressure oil in the clamping cylinder pushes the clamping mechanism, and the moving template moves to close the mold.

Step 2 – injection molding

After the mold is locked with the clamping force during the injection molding process, the injection device enters the working condition to make the nozzle and the mold fit.

Step 3-Pressure holding

during the process of filling the mold cavity, the screw is required to maintain a certain pressure on the thermoplastic material to prevent it in the mold from flowing back.

Step 4 – cooling

once the gate is sealed, the pressure holding process is canceled, and the plastic molded product is naturally cooled in the mold to shape.

Step 5 – mold opening and plastic product demolding

In order to prevent the nozzle from forming cold material due to long-term contact with the cold mold, it is usually necessary to remove the nozzle. Then evacuate the mold and molded plastic parts are demolded.

Types of Injection Molding That Baiwe Can Do

Gas assisted injection moulding

The gas-assisted injection molding system is to inject inert gas (usually nitrogen) directly into the plasticized plastic in the mold cavity through a segmented pressure control system so that the interior of the plastic part expands to form a hollow, but the appearance of the product surface is still intact.

Liquid silicone rubber injection molding

Baiwe is capable of making LSR injection molding if you need silicone rubber parts project.Such as industrial products, silicone O rings, and silicone buttons.Also consumer products, like silicone pacifiers, etc.

Overmolding

Overmolding is generally 2K injection molding, which is two-components molding. It is achieved on a two-color injection molding machine. One material is injected into the other part, and then on the two-color machine, the mold jumps to the mold cavity corresponding to another injection plastic cylinder. Injection molding of another material to make a finished product. There are silicone overmolding on plastic, silicone overmolding on metal, or plastic on metal.

Thin wall injection molding

Making smaller, lighter parts requires accurate custom injection molding, the thin wall injection molding usually consists of plastic parts with a wall thickness of less than 1mm. In any case, thinner wall sections bring changes in machining requirements: higher pressures and velocities, faster cooling time, and design of part ejection and gate of mold design. Baiwe has the production capacity of thin-wall injection molding.

What Plastic is Used for Injection Moulding?

ABS-Acrylonitrile Butadiene Styrene

ABS is a thermoplastic polymer structural material. It is mainly a polymer material synthesized by chemical substances such as acrylonitrile and butadiene. It is also called ABS resin. Because of its good heat resistance, impact resistance, and processability, it is widely used, such as children’s toys, home appliances, etc. Baiwe is capable of ABS injection molding.

PE – polyethylene

Polyethylene is odorless, non-toxic, feels like wax, has good chemical stability, has excellent low-temperature resistance, and can withstand the erosion of most acids and alkalis. It is insoluble in common solvents at room temperature, with low water absorption and excellent electrical insulation. If you are looking for PE injection molding, baiwe can be your choice.

PC – polycarbonate

PC has high strength and elastic coefficient, high impact strength, wide operating temperature range; high transparency and free dyeing; low forming shrinkage, and good dimensional stability; so PC injection molding is widely used in various industries.

PVC – PolyVinyl Chloride

PVC material is characterized by strong compression resistance, and strong toughness, and it is not easy to tear or break under construction conditions. With the same strength, the thickness of the film is much thinner than that of HDPE, and the production cost of the new material is relatively low. Baiwe provide PVC injection molding service for over 10 years.

PP – Polypropylene

PP has high crystallinity and regular structure, so it has excellent mechanical properties. However, at room temperature and low temperature, the impact strength is poor due to the high regularity of its molecular structure. The most prominent performance of PP is the resistance to bending. China is the biggest export country that makes PP injection molding.

PEEK Material

peek polyether ether ketone is a special engineering plastic with excellent properties such as high temperature resistance, self-lubrication, easy processing, and high mechanical strength, which can be manufactured and processed into various mechanical parts, such as automobile gears, oil screens, shift start disks; Aircraft engine parts, automatic washing machine runners, medical equipment parts, etc. Not every injection molding manufacturer can make PEEK injection molding in China, But Baiwe has made a lot of PEEK projects.

TPU – Thermoplastic polyurethanes

TPU material has the advantages of a large hardness range, high mechanical strength, strong cold resistance, easy processing, etc. At the same time, TPU also has disadvantages such as poor formability and hydrolysis resistance. If you want to check more about TPU injection molding, this article will help you.

Plastic Injection Molding China Cost

Generally speaking, the die steel of the core and cavity is a big factor. Steel prices vary widely in different regions. And more cavities, more expensive, In addition, the price of the runner design, hot runner, or cold runner system will affect the injection molding cost a lot.

The small, simple, single cavity injection mold can cost as little as a couple of thousand dollars. But a large, more complex high-production, multi-cavity mold can cost upwards of $10,000–$100,000 or more.

If work with Baiwe, we can make the low cost plastic injection molding if you have a tight budget, we will do our best to save the cost for your project.

We also Can Recommend You Other Plastic Injection Molding Companies

There are many plastic injection molding companies all over the world. It is very difficult to make the right choice. These companies are mainly located in China and the United States. If you need to compare injection molding manufacturers USA & injection molding manufacturers in China, you can click this article to help you make a better decision.

As one of the best plastic injection molding suppliers in China, Baiwe can provide the fastest short-run plastic injection molding with our professional services.

If you need to find other cheap plastic moulding suppliers in China, we have a list of the top 10 plastic injection molding manufacturers in china, you can check this article here. Hope it can help you.