Metal injection molding (MIM) combines powder metallurgy and plastic injection molding to manufacture small, complex metal parts at high volumes. As a professional plastic injection molding manufacturer, I am writing this guide covers everything a beginner needs to know about metal injection molding technology.

What is Metal Injection Molding?

Metal injection molding (MIM) manufactures small, intricate metal parts through injection molding. It combines fine metal powders with binder material to create a feedstock that can be injection molded.

After molding, the parts undergo debinding and sintering to remove the binders and densify the metal powders. The process facilitates large scale production of complex, tight tolerance metal components.

MIM provides design flexibility and net shape formation, allowing consolidation of assemblies into fewer parts. It is a greener alternative to machining as it generates less scrap material.

The MIM process suits a variety of industries requiring small precision metal parts like medical, automotive, firearms, and consumer products.

How Does Metal Injection Molding Work?

The metal injection molding process involves four main steps:

1. Mix Metal Powder and Binders into Feedstock

The process starts by mixing fine metal powder less than 20 microns in size with binder material, usually thermoplastics and waxes. Common MIM metals include stainless steel, titanium, tungsten alloys and copper alloys.

The feedstock comprises approximately 60% metal powder and 40% binder by volume. It has a clay-like consistency suitable for injection molding.

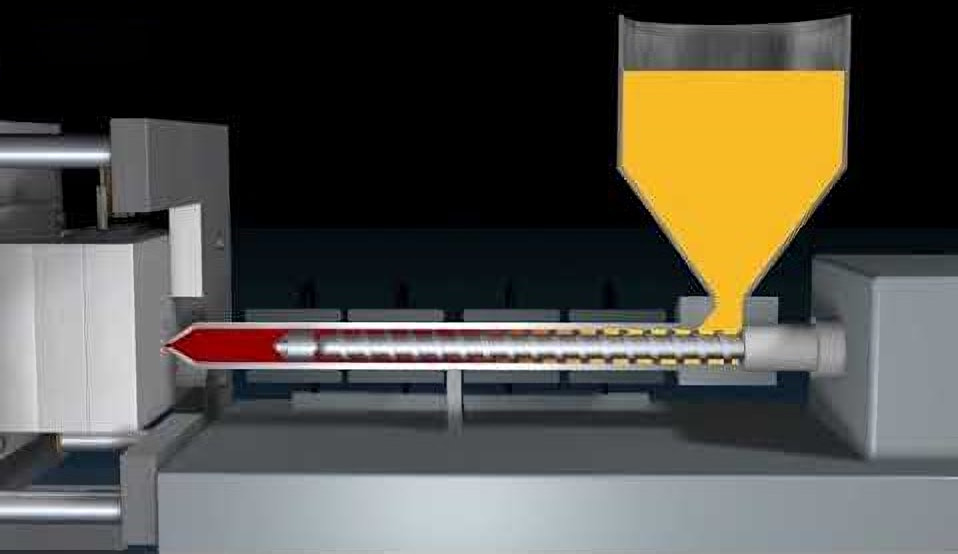

2. Injection Mold the Feedstock

Next, the feedstock enters a molding machine where it’s heated and injected into a mold cavity under high pressure. It fills the mold, taking the cavity’s shape before cooling and hardening into what’s called a “green part.”

Green parts are typically 15-20% bigger than the final components to compensate for shrinkage during sintering.

3. Remove the Binders Through Debinding

In this step, binder removal eliminates most of the polymers from the green parts. Debinding uncovers a porous structure known as the “brown part” which still retains its molded shape.

Common debinding techniques include solvent debinding, catalytic debinding, thermal debinding and supercritical fluid debinding. The process leaves some binder to help handle the brown parts.

4. Fuse the Metal Particles Through Sintering

Sintering heats the brown parts to just below the metal’s melting point inside a controlled atmosphere furnace. This fuses together the metallic particles while evaporating residual binders and reducing pores formerly occupied by binders.

Consequently, the part shrinks roughly 15% but achieves up to 97% theoretical density. The high compactness produces metal properties comparable to wrought materials.

The Benefits of Metal Injection Molding (MIM)

MIM provides several advantages over other metal manufacturing processes:

Design Flexibility

MIM facilitates intricate geometries unachievable through machining or casting. It also allows consolidation of assemblies into fewer components.

Exceptional Accuracy

MIM delivers precision tolerances between +/- 0.5% to +/- 1.5% with potential for additional post-processes where extra accuracy is required.

Material Versatility

The process works with various metals and alloys including stainless steel, titanium, tungsten and copper. It also enables graded structures by adjusting feedstock composition between shots.

Reduced Machining

MIM produces near net shape parts, minimizing material waste and eliminating extra CNC machining steps. This characteristic makes MIM a greener manufacturing approach.

Cost-Effectiveness

For small, complex components manufactured in high volumes, MIM delivers favorable unit economics compared to die casting or machining.

Common Applications of Metal Injection Molding

Here are some products manufactured through metal injection molding:

Automotive

Fuel injectors, gears, sensors and engine components like turbocharger rotors rely on MIM technology. The automotive sector continually adopts MIM for cost and weight reduction.

Aerospace

Spacecraft subsystems feature MIM parts to replace assemblies. Turbine components also leverage MIM for intricate, lightweight geometries.

Medical

Scalpels, orthodontic brackets, implants and prosthetics apply MIM to balance biocompatibility with precision engineering.

Electronics

Connector pins, micro gears and sensor assemblies achieve miniaturization and performance goals through MIM’s design freedom.

Firearms

Triggers, ejectors and safeties produced through MIM improve performance and lifetime of firearm systems.

Lifestyle Products

Intricate MIM parts find roles in wearables, sporting equipment and other lifestyle products where exacting needs exist for small metal components.

As MIM technology progresses, its applications across sectors will continue rising exponentially.

Get Your MIM Project Started

Metal injection molding delivers small, complex, tight tolerance metal components across industries like medical, aerospace and automotive.

Its unrivaled accuracy and geometric freedom produce miniaturized, highly engineered products not feasible through other metal manufacturing approaches.

MIM reimagines part consolidation while minimizing material waste for a greener production method.

Leveraging nearly fifty years of industry practice, this net shape technology creates intricate metal parts unachievable through machining or casting.

If you need precision metal components manufactured at high volumes, MIM presents a transformative production method for your application. Reach out now to discuss requirements.